|

Other important components in a cnc lathe are:

Controller System The controller system is an important component of CNC because the controller that will provide the best experience for the user as well as familiarity with the program and code used. The controller of the CNC Lathe machine consists of several well-known brands that are often used in Indonesia, namely: GSK Controller, FANUC, SIEMENS. The types for the controllers may vary and show how complex the cnc lathe is and how long/recent the controller has been on the market. Sophisticated controllers can have many additional features such as additional speed boosts and additional feeding in the middle of a program. Check track ability (feature in controller system 2016 and above) is a feature to simulate the work and motion of the coding that we have entered for the object turning process. Electrical Cabinet System Electrical Cabinet System refers to the electrical components used in the electrical panel. A good CNC machine uses the brands SIEMENS, PANASONIC, SCHNEIDER and well-known brands usually with ISO Standards and are often sold in the market. So that when there is damage, we can find a replacement at a cheap price and more freely because there are many available in the market. Servo/Inverter head Spindle Servo/Inverter spindle head distinguish rotating lathe spindle head. The inverter is a standard head spindle drive component to rotate the lathe head. The weakness of the inverter is that the rotation of the lathe spindle is not actually read in real-time. For example: When we program in Coding for S400 (speed 400 rpm) it is not necessarily in the real-time our spindle / lathe head rotates according to that number, due to many factors such as friction, loss of rotational energy due to gear transmission / fan belt / etc. On the other hand, by using a servo, there will be feedback to match the coding of the S400 with the original speed in the real-time. Then the rotation results in the real world will definitely reach 400 rpm because of the closed loop feedback system in the Servo Spindle. This is an advantage of the servo system that the inverter does not have. However, this advantage also explains a higher price Hydraulic Chuck

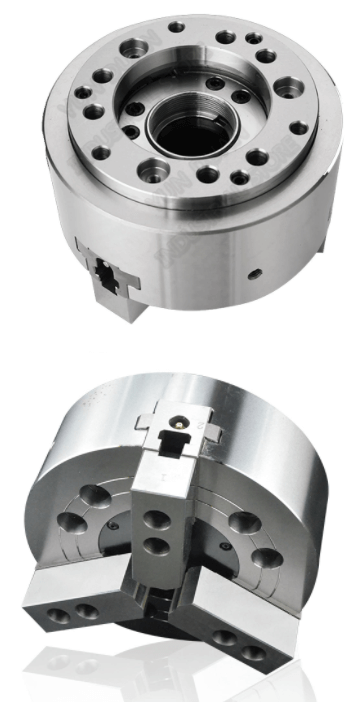

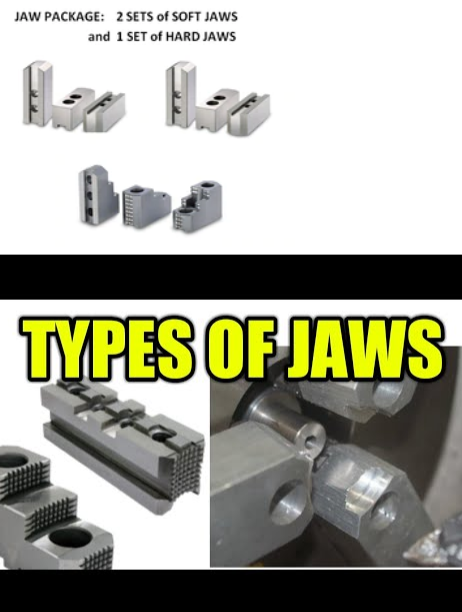

Hydraulic chuck is a vital component. Because without a hydraulic vise, the production speed and agility of a cnc machine can be ensured to be squeezed and slow because each time you have to manually tighten and remove the working material (raw material). The hydraulic chuck used must also met ISO standards so that when we set the opening / closing gap of the chuck, it is symmetrical between the three legs (3 jaw-chuck). Hydraulic chucks have two types, namely hollow and solid. Hollows have an empty hole in the middle called a thru-hole so that we can insert a longer tube through the back of the spindle. The usefulness of this hollow chuck will be even more obvious when the item is mass produced with the help of an auto feeder. While the price for Hydraulic Solid Chuck is cheaper than Hollow. Besides Solid and Hollow Hydraulic Chuck. There are also two commonly known types of jaws. Namely Soft Jaw and Hard Jaw. Although the Soft Jaw is quite expensive compared to the Hard Jaw, the Soft Jaw is a vise leg that can be turned so that the grip of the Soft Jaw can really grip your lathe. |

AuthorHenry Gunawan H Archives

November 2022

Categories

All

|

Maju Jaya MachineryJakartaMain Mobile: +62 81331333838

Mobile: +628980837368 / +6282231383858 Email: mjm168fu@yahoo.com / henrygh_mjm@yahoo.com Address: Hussain Sastra Negara, Nusa Indah Blok B No-76, Near Soetta Airport SurabayaPhone: +6231 7493838

Mobile: +62811333838 / +628980837368 Email: mjm168fu@yahoo.com / henrygh_mjm@yahoo.com Address: Margomulyo Permai Block F-20, Surabaya, Indonesia |

Sitemap |

Find Us at |

RSS Feed

RSS Feed