|

Lathe with the Baoji Brand / Brand Baoji That is distributed / agented by CV. Maju Jaya Machinery is already a popular and very known to Industrial circles in Indonesia. Baoji itself is a Group of the Bochi Group and has been manufacturing lathes since 1965. Baoji's first machine was produced by the Northwest Maintenance Station for the benefit of China's Ministry of Lathe Industry. CV. Maju Jaya Machinery is also honored with Baoji's achievements and proud to be the Authorized Distributor of Baoji Machine products. (Conventional Lathes, CNC Lathes, VMC and Machining Centers)

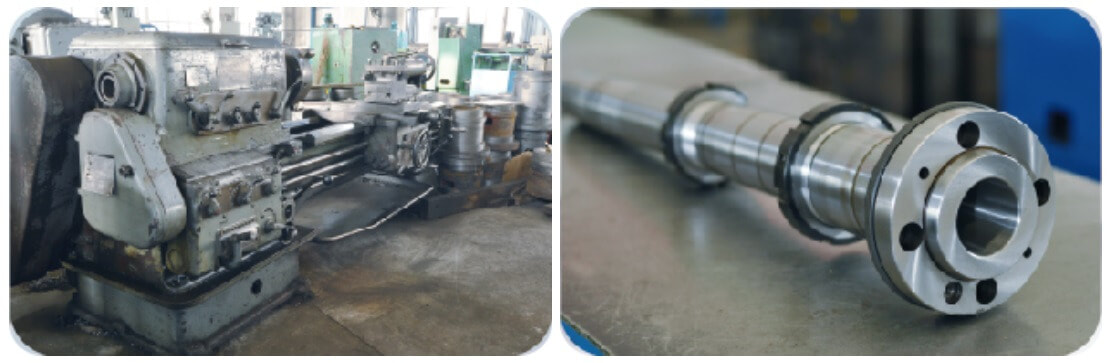

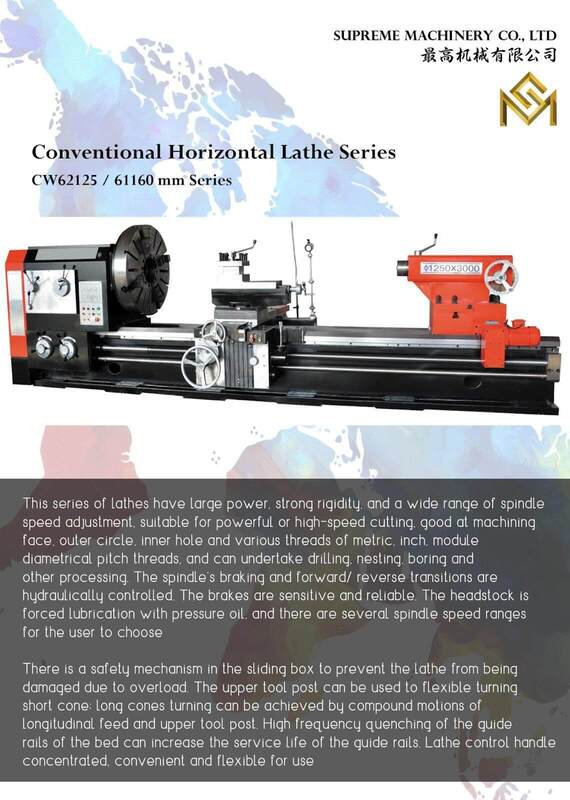

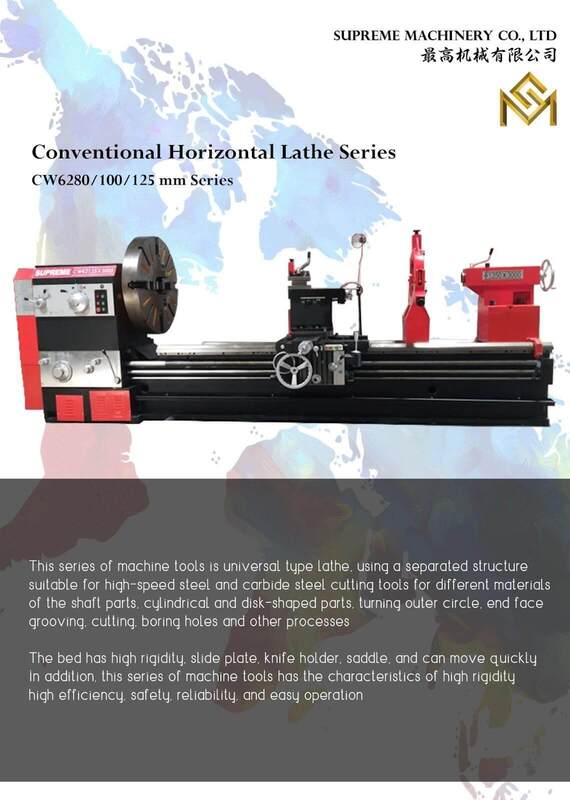

This Baoji machine is a type of lathe that has a *FULL FLOOR TYPE*, has a large Headstock Gearbox so that the main spindle bearing axles also use Double Rollers. And for threading, it is already a Non-Change Gear Type, which allows threading to work without having to change the attached gears. Most Baoji Lathes are equipped with an Automatic Feeding Gearbox, which allows for automatic work and also optional accessories in the form of Taper Attachment Equipment so that they can do tapered turning automatically. Where other Lathes do not have a 4th As-Stang, Baoji has been equipped with an Automatic Trape Handlebar AS-S. The 4th As-Stang is used so that the feeding job can be left behind and later the automatic feeding can stop at the desired position. The reliability of the Baoji Machine and also the Standardization of ISO Spare Parts have also made the Baoji Brand famous as a Tenacious and Durable machine in the machining circle. With the help of professional service workers from CV. Maju Jaya Machinery. Both from mechanical, electrical spare parts and even Usage Training (both on Baoji CNC Machines). Customers no longer need to worry about installation and back up services. CV. Maju Jaya Machinery with 32 years of experience can ensure that your business investment is on target, efficient, high productivity, and matches the company's Capex (Capital). The superiority of the Supreme CW62125 x 3000 lathe machine sold at CV. Maju Jaya Machinery8/4/2022 Supreme CW62125 x 3000 lathe machine is a type of lathe that has FULL FLOOR TYPE, it means that the body base / foot body of the lathe is Full Cast Continuously from front to back in the form of a single unit, so that the construction of the machine becomes more rigid, therefore the machine will be able to withstand the load heavy workpieces during the machining process without worrying about vibrations from heavy loading. Supreme CW62125 x 3000 lathe machine also has a lathe head construction with a larger and wider Headstock Gearbox model, as well as the main spindle axle bearing already uses heavy-duty double roller bearings, so it is capable and qualified for the *Thick* machining machining process, even without there is a concern that there will be vibrations in the axle spindle, so that the output of the machining workpiece is guaranteed to be precise. This machine has an agile character with the application of several features into the construction of the driving system mechanism of this machine, namely for the lathe machining process, various types of threads, both for the Metric to Inch system and for the Drain Module and Diametral Pitch threads, all of which can be done on this machine quickly and easily. efficient without the hassle of changing the gear arrangement in addition to the headstock, because it has implemented the Non Change Gears Type process system.

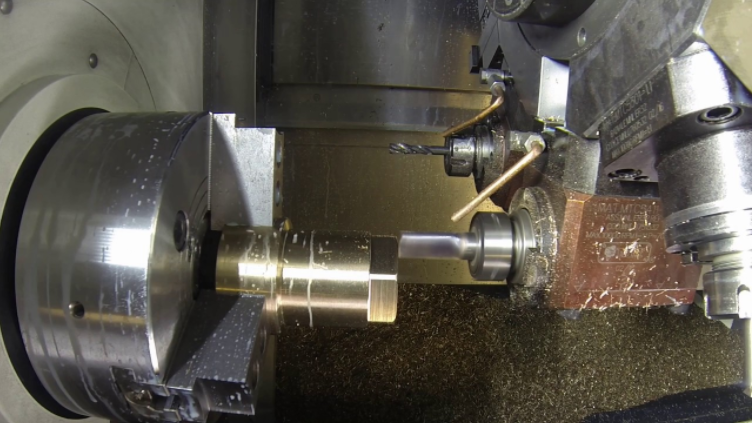

The machine is also equipped with a Rapid Traverse Motor apparatus to make it easier for the operator of this machine when he encounters a long iron axle machining job that requires several repetitions of the lathe knife incision from end to end of the long iron axle and this job of course requires traveling carriage several times automatically. This machine is also equipped with the Automatic Taper Turning feature, which is applied to the construction of the driving system in the form of Auto Feeding Upper Tools Rest so that this machine is able to do lathe work with Conus degree deviation consistently and the result can be ensured that the Conus degree precision is as desired. This machine has also adopted the Coupling Hydraulic system for driving the machine's main Spindle rotation system, with this hydraulic system, the spindle rotation of this machine is able to produce a larger cutting power output and can produce a stable and consistent rotation speed per minute in various fields. variations of the spindle rotation of this machine. This machine has a very wide Effective Gap Length which is up to 340mm, and this size is free starting from the front of the 4-foot lathe vise with a diameter of 1000mm, so the ability to lathe workpieces with a diameter of 1500mm can still reach for the thickness of the workpiece sd 340mm, which is still able to rotate freely on the Swing in Gap of this machine. Other important components in a cnc lathe are:

Controller System The controller system is an important component of CNC because the controller that will provide the best experience for the user as well as familiarity with the program and code used. The controller of the CNC Lathe machine consists of several well-known brands that are often used in Indonesia, namely: GSK Controller, FANUC, SIEMENS. The types for the controllers may vary and show how complex the cnc lathe is and how long/recent the controller has been on the market. Sophisticated controllers can have many additional features such as additional speed boosts and additional feeding in the middle of a program. Check track ability (feature in controller system 2016 and above) is a feature to simulate the work and motion of the coding that we have entered for the object turning process. Electrical Cabinet System Electrical Cabinet System refers to the electrical components used in the electrical panel. A good CNC machine uses the brands SIEMENS, PANASONIC, SCHNEIDER and well-known brands usually with ISO Standards and are often sold in the market. So that when there is damage, we can find a replacement at a cheap price and more freely because there are many available in the market. Servo/Inverter head Spindle Servo/Inverter spindle head distinguish rotating lathe spindle head. The inverter is a standard head spindle drive component to rotate the lathe head. The weakness of the inverter is that the rotation of the lathe spindle is not actually read in real-time. For example: When we program in Coding for S400 (speed 400 rpm) it is not necessarily in the real-time our spindle / lathe head rotates according to that number, due to many factors such as friction, loss of rotational energy due to gear transmission / fan belt / etc. On the other hand, by using a servo, there will be feedback to match the coding of the S400 with the original speed in the real-time. Then the rotation results in the real world will definitely reach 400 rpm because of the closed loop feedback system in the Servo Spindle. This is an advantage of the servo system that the inverter does not have. However, this advantage also explains a higher price Hydraulic Chuck

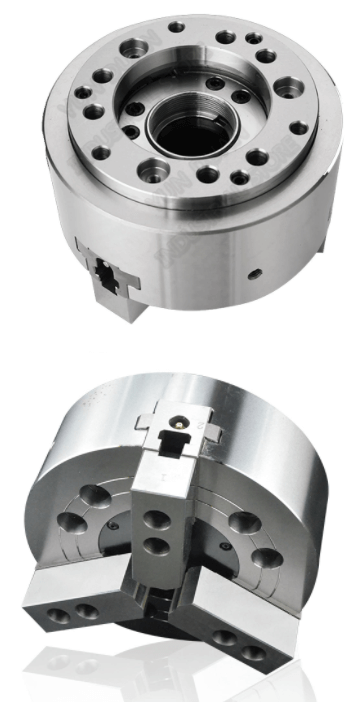

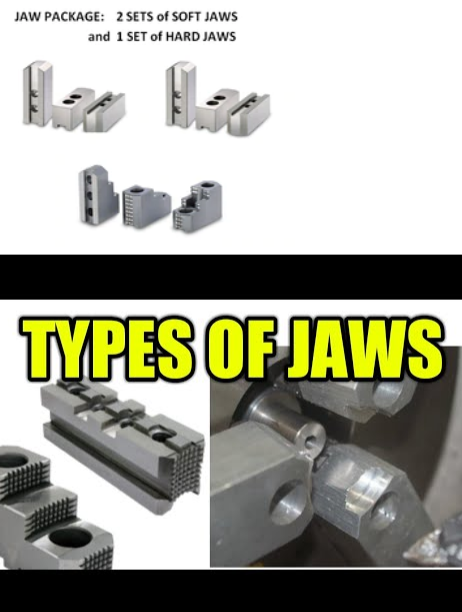

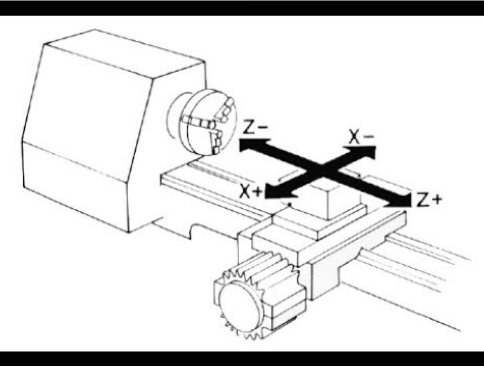

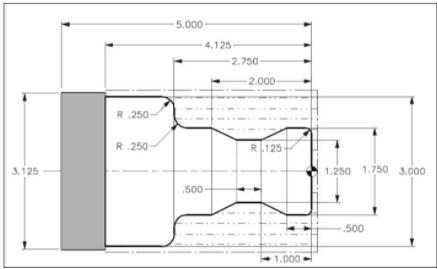

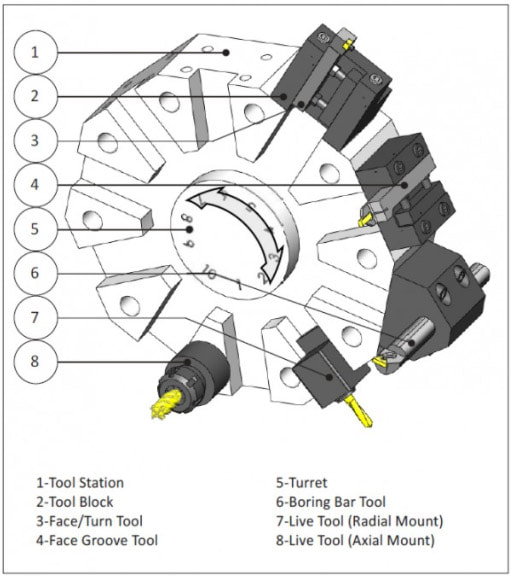

Hydraulic chuck is a vital component. Because without a hydraulic vise, the production speed and agility of a cnc machine can be ensured to be squeezed and slow because each time you have to manually tighten and remove the working material (raw material). The hydraulic chuck used must also met ISO standards so that when we set the opening / closing gap of the chuck, it is symmetrical between the three legs (3 jaw-chuck). Hydraulic chucks have two types, namely hollow and solid. Hollows have an empty hole in the middle called a thru-hole so that we can insert a longer tube through the back of the spindle. The usefulness of this hollow chuck will be even more obvious when the item is mass produced with the help of an auto feeder. While the price for Hydraulic Solid Chuck is cheaper than Hollow. Besides Solid and Hollow Hydraulic Chuck. There are also two commonly known types of jaws. Namely Soft Jaw and Hard Jaw. Although the Soft Jaw is quite expensive compared to the Hard Jaw, the Soft Jaw is a vise leg that can be turned so that the grip of the Soft Jaw can really grip your lathe. 2-axis CNC Lathe Baca: Important Components in a CNC Lathe 2 axis CNC lathe is a lathe which is a basic cnc lathe. The machine has X and Z axis as well as Axis Rotation to work on the item. The workmanship of this 2-axis CNC lathe is quite simple and easy and includes Roughing, Cutting / Finishing, Grooving, Threading, Chamfering / Tapering like a manual lathe. The working drawing of this 2 axis CNC lathe is also relatively simple as shown in the example below: 3-axis CNC Lathe 3 axis CNC lathe is a more complex CNC lathe because it adds Drilling / Tapping and Milling Operation features to the machine. This 3 axis Lathe CNC machine can form more complex workpieces and does not always have to be based on round shapes. The vise head of a 3 axis CNC lathe is an index head that can read how many degrees the object has rotated which allows the work of the installed milling tool.

CNC Lathe Machine is a lathe that is controlled / integrated with a Computer Numerical Control system. CNC lathes have the same mechanism and principles as manual lathes / conventional lathes. It's just that the CNC lathe has been perfected which makes this machine have a precision and speed that far exceeds the manual. The CNC lathe can hold multiple holders and insert blades which facilitates production automation and reduces production time. The CNC lathe is a large quantity production machine. READ: Definition of Lathe Machine The basic components that have been discussed in previous blogs are: 1. Lathe Head 2. Tail Lathe 3. Sledge 4. Lathe Table It should not be forgotten and the size of this component is also a vital aspect so that the lathe can cut thick materials more rigidly and easily. The advantages of CNC Lathes compared to Conventional Lathes are: 1. No need to spend time grinding or sharpening the lathe. CNC Lathes already have to use tool holders and CNC inserts to be efficient. After the Insert is finished, just exchange it with a new Insert / Use the other side of the insert. 2. After the Insert is Reinstalled, there is no need to reset the Zero point of the Tool Holder and can immediately return to production.

3. Machine programs can be saved and recalled at any time, and can also be resized easily. If there is a lack of workmanship in terms of size, then the tool can be offset according to the size that is lacking in order to produce precise finished goods. 4. The high spindle speed and constant cutting process that can be produced by the CNC Lathe machine produce shiny and good results without the need for another grinding process. 5. Size and Contour of 1000 items produced will produce the same results. Precision so as to minimize human error / human measurement error. Lathe is one of the most common and basic workshop machines in a workshop. Lathe as it is known today was created since the Egyptian Civilization and was popularized by the UK as one of the industrial machines that produces components or parts. Lathe is a machine / tool that uses the principle of rotation as a basis. The workpiece will be gripped by the Chuck / Vise and rotated against the Cutting Tools / Chisel / Cutting Knife thus giving us the desired contour / shape / shape. The function of the Lathe is diverse and can include materials such as: iron, stainless steel, brass, silver, wood and plastic. In working on a workpiece, there are several basic functions, namely:

The five processes above are general processes that can be carried out by lathes and each process requires different chisels / lathe blades, different spindle speed and feeding parameters and different results on the workpiece. Roughing is a repeated process of cutting basic materials quickly, thickly and roughly. The purpose of roughing is to make the basic shape / shaping roughly so that the remaining material that must be peeled / turned by the finishing / cutting knife is not much. Cutting / Finishing is the process of cutting the final material so that it becomes a final product with an accurate size and according to tolerance. Usually the cutting / finishing work does not last long and is not repeated and uses high speed so that the results can look smooth and shiny. Grooving is the process of cutting material to produce a groove or bag. The width of a gutter or coke depends on the blade used. Threading is the process of cutting material so that the material can have the desired thread. Parameters of Threading / Thread / Thread can be seen in the column listed on the lathe and adjusted to the blade. Chamfering / Tapering is the process of finishing a material so that the edges of the material are not sharp. This is useful to ensure that the product is safe for humans and facilitate the use of the product. On the other hand, Chamfering / Tapering can add to the aesthetics and quality of a final product. Main Components of a Lathe MachineLathe Head (Headstock) The head of the lathe is located on the part that has a spindle / place for rotating goods. On the headstock there are also levers that are useful for adjusting the spindle rotation speed. The Lathe Head / Vise Lathe can be changed to a vise 3 clamps or 4 grippers. Tail Lathe (Tailstock) The tail of the lathe is opposite the lathe head. Tail Lathe functions on a lathe with two centers, to avoid bending the workpiece during the turning process, for example in turning a long axle, so that the long axle is not flexible and does not sway when turning. The tail of the lathe also serves so that the object being turned can get a good center / tolerance. Carriage Carriage is a support table and tool station carrier / where the lathe blade rests. Without this table, the lathe will not function because there is no knife to carve objects. This table is also mostly equipped with automatic feeding and travel to make it easier for the operator to control it & has a coolant hose to spray drum oil for cooling down friction of the workpiece. Lathe Table (Lathe Bed)

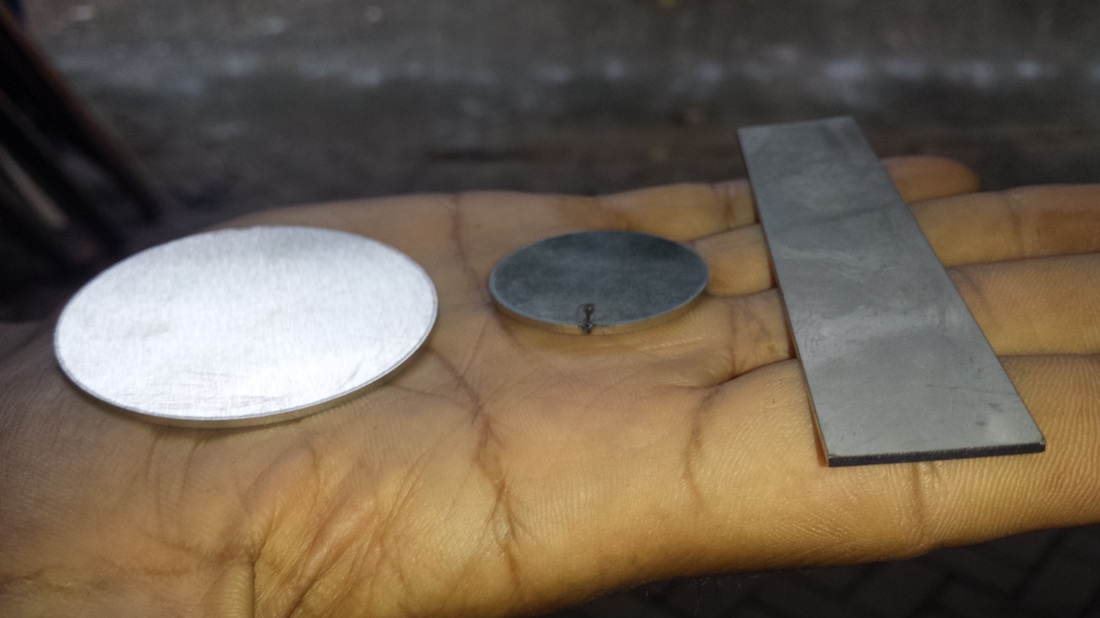

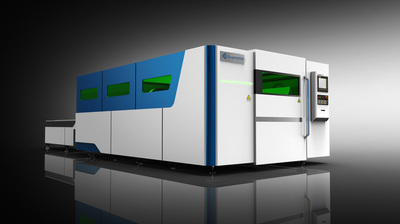

The Lathe Table is the basic framework of the lathe and is the strength / core of the lathe that cannot be fooled. Lathe table and its width is the foundation of the head, tail of the lathe and also the sled. The width of the lathe is very influential for the stability of the workpiece cutting and the feeding strength of the lathe. The wider the bed, the more sturdy the machine and more tread so that the work can be eaten thickly without even shaking. Hi all, Good Day to you We haven't updated our blog since last April because of our shortage in time. While we have the time needed to update our blog. Today i would like to thank Mr. G From GT in Jember, Indonesia for investing on SUPREME FIBER LASER Machine from Maju Jaya Machinery. The training began and lasted for 5 days which include the preparation, installation and teaching the operator to fully operate & maintain the machine. For these 5 days we do our best to tune the machine into the best condition for optimum performance. Below are our photo with our customer. Today, it's been 2 months since we last installed and train GT and i just have the time to update the blog. GT has been our loyal customer since early 2000's and also had purchase two Press Brake / Bending machine. Here are some example for the product sample (Stainless Steel 2 mm) that we cut at our customer site and we also have uploaded video of our SUPREME FIBER LASER CUTTING machine. That is all. Thanks folk for reading this blog. :)

Hi, this is MJM and we would like to greet you with our best products: CNC Machines! We want to give you some insights on CNC machine and invite you to come to our workshop located at Surabaya, East Java. We have various CNC machine imported from Japan and China ready in our workshop. Please feel free to visit us!

But before that, some of you might wonder on why you should choose or buy CNC machine? MJM provides industrial machines for metal cutting and finishing, and our main products are CNC machines. CNC stands for Computer Numerically Controlled, it means that the machine will be controlled by some instructions such as position coordination generated by computer. CNC machine uses a rotating cutting tool to cut out or carve material parts. CNC is very versatile and able to cut variety of different materials. There are many types of CNC machine, but we provide two types of the most popular CNC machines; CNC lathe and CNC Wire Cut machines. Hi all, Starting from Today, we've got a brand new product that will be on the market. These are the fiber lasers machine, fiber lasers machine are capable to cut through Stainless-Steel, Mild steel and Carbon Steel in an efficient and extremely productive method. Its speed of cutting is up top 20cm/second an its product is very refine. This is possible because the transmission that we tend to use is neither ballscrew nor Standard Rack and Pinion Gear. The precision is also supported by it's slant type design.

Hi All!

Now our website is Bilingual, one in English and the other one is Indonesian. Feel free to visit both of the website depend on your language selection. Secondly, the reason why this website needs Indonesian version is because of the eligibility and to help the SEO(Search Engine Optimization) of Google to place this web in the first page/ top rating. To maximize your SEO, this weebly article could help you greatly in starting your own website. Another Tips and Trick to get your website on the top of Google search list, you can:

That's all for today post folks! Thank you for your attention! |

AuthorHenry Gunawan H Archives

November 2022

Categories

All

|

Maju Jaya MachineryJakartaMain Mobile: +62 81331333838

Mobile: +628883020992 / +6282231383858 Email: mjm168fu@yahoo.com / henrygh_mjm@yahoo.com Address: Hussain Sastra Negara, Nusa Indah Blok B No-76, Near Soetta Airport SurabayaPhone: +6231 7493838

Mobile: +62811333838 / +628883020992 Email: mjm168fu@yahoo.com / henrygh_mjm@yahoo.com Address: Margomulyo Permai Block F-20, Surabaya, Indonesia |

Sitemap |

Find Us at |

RSS Feed

RSS Feed